Plan Drawing Transverse Truss Fr

A truss is essentially a triangulated organisation of straight interconnected structural elements. The most mutual use of trusses is in buildings, where back up to roofs, the floors and internal loading such as services and suspended ceilings, are readily provided. The master reasons for using trusses are:

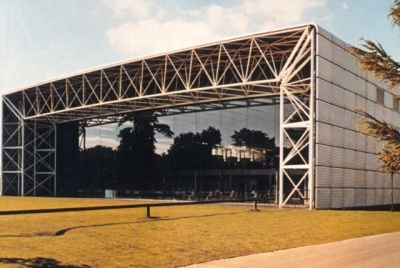

Long-bridge, curved roof trusses

Robin Hood Airport, Doncaster

(Prototype courtesy of Tubecon)

- Long bridge

- Lightweight

- Reduced deflection (compared to apparently members)

- Opportunity to support considerable loads.

The penalty, however, is increased fabrication costs .

The article describes alternative forms of truss, where and why different forms might be appropriate and introduces pattern considerations. Primarily, pin jointed trusses are discussed, with some word of rigid-jointed Vierendeel trusses.

[meridian] Definition of a truss

Members under axial forces in a elementary truss

one - Compression axial force

2 - Tension axial forcefulness

A truss is essentially a triangulated system of (ordinarily) straight interconnected structural elements; it is sometimes also referred to as an open web girder. The private elements are continued at nodes; the connections are oft assumed to be nominally pinned. The external forces practical to the system and the reactions at the supports are generally applied at the nodes. When all the members and applied forces are in a same plane, the arrangement is a aeroplane or 2D truss.

The principal force in each element in a truss is axial tension or pinch.

Overview of trusses

[pinnacle] Utilise of trusses in buildings

Trusses are used in a broad range of buildings, mainly where in that location is a requirement for very long spans, such as in airdrome terminals, shipping hangers, sports stadia roofs, auditoriums and other leisure buildings. Trusses are as well used to bear heavy loads and are sometimes used equally transfer structures. This article focuses on typical single storey industrial buildings, where trusses are widely used to serve two main functions:

- To bear the roof load

- To provide horizontal stability.

Two types of full general arrangement of the structure of a typical single storey building are shown in the figure beneath.

|  |

| Lateral stability provided by portal trusses. No longitudinal current of air girder. | Building braced in both directions. Longitudinal stability provided by transverse wind girder and vertical bracings (green) |

In the starting time case (left) the lateral stability of the structure is provided past a series of portal trusses; the connections betwixt the truss and the columns provide resistance to a global bending moment. Loads are applied to the portal structure by purlins and side rails.

In the 2nd case, (right) each truss and the two columns betwixt which information technology spans, constitute a simple structure; the connection between the truss and a cavalcade does non resist the global bending moment, and the 2 column bases are pinned. Bracing in both directions is necessary at the meridian level of the simple structure; information technology is accomplished by means of a longitudinal wind girder which carries the transverse forces due to current of air on the side walls to the vertical bracing in the gable walls. Longitudinal stability is besides provided past a wind girder in the roof and vertical bracing in the elevations.

[top] Types of trusses

Trusses comprise assemblies of tension and compression elements. Under gravity loads, the peak and bottom chords of the truss provide the compression and tension resistance to overall bending, and the bracing resists the shear forces. A wide range of truss forms can be created. Each tin vary in overall geometry and in the choice of the individual elements. Some of the ordinarily used types are shown below.

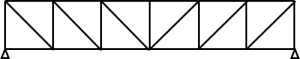

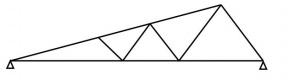

[top] Pratt truss ('N' truss)

Pratt trusses are ordinarily used in long span buildings ranging from twenty to 100 m in span. In a conventional Pratt truss, diagonal members are in tension for gravity loads. This type of truss is used where gravity loads are predominant (meet below left). An culling Pratt truss is shown (below right) where the diagonal members are in tension for uplift loads. This type of truss is used where uplift loads are predominant, which may be the case in open buildings such as aircraft hangers.

-

Pratt truss (gravity loads)

-

Pratt truss (uplift loads)

Information technology is possible to add secondary members (as illustrated below left) to:

- Create intermediate support points for practical loads

- Limit the buckling length of members in compression (although in a 2D truss, the buckling length is but modified in i centrality).

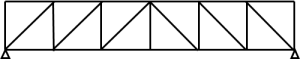

For the Pratt truss and whatsoever of the types of truss mentioned below, it is possible to provide either a single or a double slope to the upper chord of a roof supporting truss. An instance of a double (duo-pitch) Pratt truss is shown below.

-

Pratt truss with secondary members

-

Duo-pitch Pratt truss

A Pratt truss – University of Manchester

(Image courtesy of Elland Steel Structures Ltd.)

[top] Warren truss

Modified Warren trusses – National Composites Centre, Bristol

(Image courtesy of Billington Structures Ltd.)

In this type of truss, diagonal members are alternatively in tension and in compression. The Warren truss has equal length compression and tension web members, and fewer members than a Pratt truss. A modified Warren truss may exist adopted where additional members are introduced to provide a node at (for example) purlin locations.

Warren trusses are commonly used in long span buildings ranging from 20 to 100 grand in span.

This type of truss is likewise used for the horizontal truss of gantry/crane girders.

Modified Warren truss

[superlative] North light truss

Due north Lite truss

North calorie-free trusses are traditionally used for short spans in industrial workshop-type buildings. They allow maximum do good to be gained from natural lighting by the use of glazing on the steeper pitch which by and large faces north or northward-e to reduce solar gain. On the steeper sloping portion of the truss, it is typical to have a truss running perpendicular to the plane of the North Light truss, to provide large cavalcade-costless spaces.

The utilise of north lights to increment natural daylighting can reduce the operational carbon emissions of buildings although their bear on should be explored using dynamic thermal modelling. Although north lights reduce the requirement for artificial lighting and can reduce the gamble of overheating, past increasing the volume of the edifice they can also increase the need for infinite heating. Further guidance is given in the Target Nada Warehouse buildings design guide .

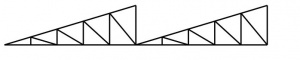

[top] Saw-molar truss

Saw-tooth (or Butterfly) truss

A variation of the North lite truss is the saw-tooth truss which is used in multi-bay buildings. Like to the North calorie-free truss, information technology is typical to include a truss of the vertical face running perpendicular to the plane of the saw-tooth truss.

[top] Fink truss

Fink truss

The Fink truss offers economy in terms of steel weight for curt-span high-pitched roofs every bit the members are subdivided into shorter elements. At that place are many ways of arranging and subdividing the chords and internal members.

This type of truss is unremarkably used to construct roofs in houses.

[top] Aspects of truss blueprint for roofs

[height] Truss or I beam

For the same steel weight, it is possible to go better performance in terms of resistance and stiffness, with a truss than an I beam. This divergence is greater for long spans and/or heavy loads. The full use of this advantage is achievable if the pinnacle of the truss is not limited by criteria other than the structural efficiency, e.g. a limit on total height of the building. Even so, fabrication of a truss is more often than not more than time consuming than for an I beam, even because that modernistic fabrication equipment is highly efficient.

The residual between minimum weight and minimum cost depends on many atmospheric condition: the equipment of the fabrication factory, the local cost of manufacturing; the steel unit of measurement cost, etc. Trusses by and large give an economic solution for spans over 20 m.

An advantage of the truss blueprint for roofs is that ducts and pipes that are required for functioning of the buildings services can be installed through the truss web, i.due east. service integration.

[top] General geometry

For efficient structural functioning, the ratio of bridge to truss depth should be chosen in the range 10 to 15. The architectural pattern of the building determines its external geometry and governs the gradient(southward) given to the top chord of the truss. The intended use of the internal space can lead either to the choice of a horizontal bottom chord, due east.g. where conveyors must be hung under the chord, or to an inclined lesser chord, to allow maximum space to be provided.

For an efficient layout of the truss members between the chords, the following is appropriate:

- The inclination of the diagonal members in relation to the chords should be between 35° and 55°

- Point loads should only be applied at nodes

- The orientation of the diagonal members should exist such that the longest members are subject area to tension (the shorter ones being discipline to compression).

[top] Types of truss member sections

Bolted angles to form lightweight, long-span trusses

(Prototype courtesy of Metsec plc)

Many solutions are available. Choice of members depends on the magnitude of the internal forces, ease of connections between members, aesthetics and whatever necessity to connect prefabricated truss sections on site. When selecting members, the out-of-airplane buckling resistance will be important, together with resistance nether reversed loading, for instance, uplift.

Typical chemical element cross sections for light building trusses

For smaller spans, tee sections are frequently used for chords, with angles used every bit internal members. The internal members may be bolted or welded to the tees. Back-to-back angles or channels may exist used for longer spans or heavier loads, with a gusset plate used at nodes to connect the members.

For big trusses and heavy loads, typically found in transfer trusses in buildings, members may be rolled sections; typically UKC sections. Nodes are usually welded. Any necessary connections are completed with bolted splices within the length between nodes.

For many exposed trusses, hollow sections are chosen for their structural efficiency and for aesthetic reasons. Nodes will generally exist welded in the workshop. As part of the truss design, information technology is essential to verify the resistance of the joints (in accordance with BS EN 1993-ane-8[1]) as the joint design may dominate fellow member option and final truss geometry. Members should be selected carefully to avoid expensive strengthening of trusses fabricated from hollow sections.

Different types of steel department used in trusses

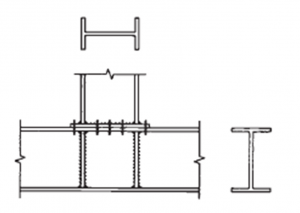

[height] Types of connections

|  |

For all the types of fellow member sections, it is possible to pattern either bolted or welded connections. Generally in steelwork construction, bolted site splices are preferred to welded splices for economy and speed of erection. Where bolted connections are used, it is necessary to evaluate the consequences of 'slack' in connections. In guild to reduce these consequences (typically, the increment of the deflections), pre-loaded assemblies to produce non-slip joints are recommended.

Hollow sections are typically connected by welding whilst open up sections are connected past bolting or welding, which will usually involve the employ of gusset plates. Guidance on the design of welded joints for Celsius®355 and Hybox®355 hollow sections is available from Tata Steel.

Minor trusses which can be transported whole from the fabrication factory to the site, tin can exist entirely welded. In the case of big roof trusses which cannot be transported whole, welded sub-assemblies are delivered to site and are either bolted or welded together on site.

In light roof trusses, entirely bolted connections are less favoured than welded connections due to the requirement for gusset plates and their increased fabrication costs.

Profile shaping of tubular sections for articulation fabrication

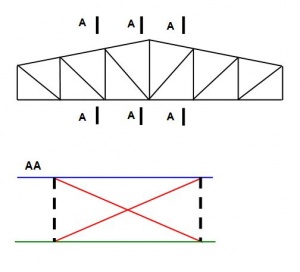

[meridian] Lateral stability

It is necessary to design members in compression against out-of-airplane buckling. For simply supported trusses, the upper chord is in pinch for gravity loading, and the bottom chord is in compression for uplift loading. For portal trusses, each chord is partly in compression and partly in tension.

Lateral restraint of the upper chord is generally given past the purlins and the transverse roof air current girder.

For the restraint of the bottom chord, boosted bracing may exist necessary, every bit shown below. Such bracing allows the buckling length of the lesser chord to be limited out of the aeroplane of the truss to the distance between points laterally restrained; the diagonal members transfer the restraint forces to the level of the meridian chord, where the general roof bracing is provided.

| Fundamental Thick black dashes - 2 consecutive trusses Blue - The purlin which completes the bracing in the upper region |

It is possible to create a horizontal wind girder at the level of the bottom chords, with longitudinal elements to stabilize all the trusses.

[peak] Pattern of wind girders

[peak] Transverse wind girder

In full general, the form of a transverse wind girder is as follows:

- The wind girder is arranged equally a Warren or Pratt truss, parallel to the roof plane

- The chords of the air current girder are the upper chords of ii adjacent vertical trusses. This ways that the axial forces in these members due to loading on the vertical truss and those due to loads on the wind girder loading must exist added together (for an advisable combination of actions)

It is user-friendly to conform a transverse wind girder at each end of the building so that the longitudinal members need act merely in tension.

[top] Longitudinal wind girder

It is necessary to provide a longitudinal wind girder (between braced gable ends) in buildings where the roof trusses are not 'portalized'.

The full general system is similar to that described for a transverse wind girder:

- Warren or Pratt truss

- Generally, chord members volition be provided from hollow sections

- The posts (if required) are the upper chords of the consecutive stabilized roof trusses.

[height] Guidance on global assay

Although joints in trusses are ofttimes inappreciably pinned in reality, it is more often than not satisfactory (and encouraged by blueprint Standards) to presume the joints are pinned and to verify the members for axial load only.

If loads are applied between nodes, trusses are oftentimes analysed with continuous chords, but with all internal members pinned. These assumptions about pinned joint behaviour apply to both bolted and welded connections.

Where member centre lines practise non intersect at a node (the articulation geometry may take been adjusted to increase the strength of the joint), the additional moments produced by the eccentricity are usually allowed for in the pattern of the chord members.

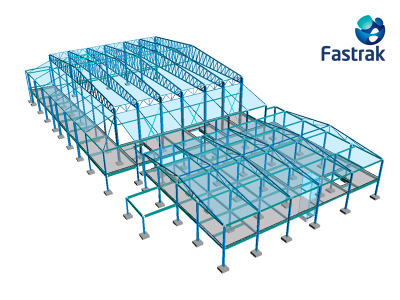

[elevation] Modelling

Fastrak truss structure model

(Fastrak model courtesy of Trimble)

Several questions arise in respect of the modelling of a truss.

It is usually convenient to work on restricted models. For instance, for a standard building, it is common and usually justified to piece of work with second models (portal, air current girder, vertical bracing) rather than a global 3D model. A truss can be modelled without its supporting columns when it is articulated to the columns.

Nonetheless, it is important to note that:

- If separate models are used, it may be necessary, in order to verify the resistance of certain elements, to combine the results of several analyses; example: the upper chord of a truss besides serves equally chord of the current of air girder.

- If a global 3D model is used and appropriate member releases not provided, 'parasitic' bending can be observed, which oftentimes only creates an illusory precision of the structural behaviour.

For trusses, 2 assay models are unremarkably used, either:

- Continuous chords with pinned internals, or

- Pinned joints throughout the truss.

[summit] The outcome of non-preloaded assemblies on truss deflection

When the connections between elements which make upwardly a truss are bolted, with bolts in shear and bearing (category A in BS EN 1993-1-8[1] ), the clearance introduced into these connections (which allows sideslip) can take a pregnant event on displacement of the nodes.

In guild to facilitate erection, the bolts are located in holes which are larger than the bolts themselves. For standard commodities sizes, holes which are ii mm bigger than the bolt are usually made (usually referred to equally a clearance pigsty).

Tubular trusses as an aestetic feature in a single storey building

In order for a connexion with clearance holes to transmit the load, the bolt must come into contact with one or other of the connected parts which allows skid in the connection. For a continued tension member, this slip tin can exist considered equally an additional extension that is added to the elastic elongation of the member in tension. Likewise, for a connected pinch member, the slip is considered equally a reduction in length that is added to the elastic shortening of the compressed member.

The total slip in the many dissimilar connections of a truss structure tin atomic number 82 to a pregnant increase in displacements, which tin take more or less serious consequences:

- In most of the cases, the visual effect is the worst consequence

- Increased deflection tin can lead to a reduction of costless height under the bottom chord, which might prevent or upset the anticipated usage. For example, the additional deflection of a truss holding doors suspended in a gable of an plane hangar could prevent the smooth operation of the doors

- Increment in the deflection tin result in reduction in the slope of the supported roof and even, if the nominal slope were small, to a gradient inversion; the risk of water ingress is increased.

Information technology is therefore essential, where truss structures are concerned, to control the consequence of connection slack on the displacements. In club to practise this, information technology is oft necessary:

- To use preloaded bolts (category B or C connections); or

- To use welded connections instead of bolted connections.

[acme] Detailed design considerations for elements

Truss members are subjected to axial force, simply may also be subjected to bending moments, for instance, if the chords have been modelled every bit continuous.

[top] Verification of members under compression

The resistance of a fellow member to compression is evaluated by taking into account the different modes of instability:

- Local buckling of the section is controlled using section classification

- Buckling of the member is controlled by applying a reduction factor to the resistance of the cross-section.

In virtually truss members, only flexural buckling of the compressed members in the aeroplane of the truss structure and out of the plane of the truss structure demand be evaluated.

The buckling resistance is obtained from BS EN 1993-i-1[2] past applying a reduction to the resistance of the cross-section. This reduction cistron is obtained from the slenderness of the fellow member, which depends on the elastic critical force.

For the diagonals and the verticals stressed in uniform compression the rubberband critical force is adamant from the buckling length of the member in accordance with BS EN 1993-i-1[two] Section 6.iii.i.3 and according to Annex BB of BS EN 1993-1-1[2] :

- For buckling in the plane of the truss, the buckling length is taken equal to 90% of the organisation length (distance between nodes), when the truss member is connected at each end with at least two bolts, or by welding.

- For buckling out of plane of the truss beam, the buckling length is taken equal to the system length.

For buckling in the plane of the truss of the chord members in compatible compression, the buckling length may be taken equally 90% of its system length (distance betwixt nodes).

For buckling out of plane of the truss, the buckling length must be taken between lateral back up points.

In the worked example, where the truss supports a roof, with purlins at the level of the upper chord of the truss:

- All the purlins connected to a roof bracing tin can exist considered equally lateral rigid support points.

- Intermediate purlins can also exist considered as a rigid point of support, if the roof behaves as a diaphragm (class 2 construction co-ordinate to BS EN 1993-1-3[3]).

- Lateral support points are provided to the lower chord by additional vertical bracing elements between trusses.

[top] Vierendeel trusses

[top] Use of Vierendeel trusses

Vierendeel truss

Vierendeel trusses are rigidly-jointed trusses having only vertical members betwixt the top and bottom chords. The chords are normally parallel or about parallel.

Elements in Vierendeel trusses are subjected to angle, centric force and shear , unlike conventional trusses with diagonal web members where the members are primarily designed for centric loads.

Vierendeel trusses are unremarkably more than expensive than conventional trusses and their use limited to instances where diagonal web members are either obtrusive or undesirable.

Vierendeel trusses are moment resisting. Vertical members near the supports are subject to the highest moments and therefore crave larger sections to be used than those at mid-span. Considerable bending moments must be transferred between the verticals and the chords, which tin can result in expensive stiffened details.

[peak] Analysis

As Vierendeel trusses are statically indeterminate structures, computer analysis software packages are generally used to analyse the truss.

[top] Connections

Vierendeel trusses have rigid joints which must transfer significant angle moments, especially near the supports. Welded joints are therefore mutual and may involve significant local reinforcement of the members at the joint. If joints are bolted, substantial connections will be necessary, mostly using pre-loaded bolts.

|  |

[top] References

- ↑ 1.0 1.1 BS EN 1993-i-8:2005. Eurocode 3: Blueprint of steel structures. Design of joints, BSI

- ↑ 2.0 2.1 2.2 BS EN 1993-1-1:2005+A1:2014, Eurocode three: Design of steel structures. General rules and rules for buildings, BSI

- ↑ BS EN 1993-1-three:2006 Eurocode three. Design of steel structures. General rules. Supplementary rules for cold-formed members and sheeting, BSI

[top] Further reading

- Steel Designers' Manual seventh Edition. Editors B Davison & 1000 W Owens. The Steel Construction Institute 2012, Chapter 20, Trusses

- Architectural Design in Steel – Trebilcock P and Lawson R Thou published past Spon, 2004

[top] Resource

- Target Zippo: Guidance on the blueprint and construction of sustainable, low carbon warehouse buildings

- SCI P167 Architectural Teaching Resources. Studio Guide. SCI and Corus, 2003

- NCCI: Design of roof trusses SN027a-EN-Eu

- Scheme Development: Conceptual pattern of truss and column solutions SS050a-EN-EU

- Case: Single bridge truss and postal service frame for a low pitch roof using battened section chords SX017a-EN-European union

- Single-Storey Steel Buildings Part 5: Articulation design, The Steel Alliance

- Pattern of welded joints - Celsius®355 and Hybox®355, 2013, Tata Steel

[top] See also

- Single storey industrial buildings

- Cost of structural steelwork

- Operational carbon

- Target Zero

- Fabrication

- Welding

- Construction

- Preloaded bolting

- Steel construction products

- Simple connections

- Moment resisting connections

- Modelling and analysis

- Fellow member design

[superlative] External links

- Trimble

Source: https://www.steelconstruction.info/Trusses

0 Response to "Plan Drawing Transverse Truss Fr"

Post a Comment